- Fire fighting machine

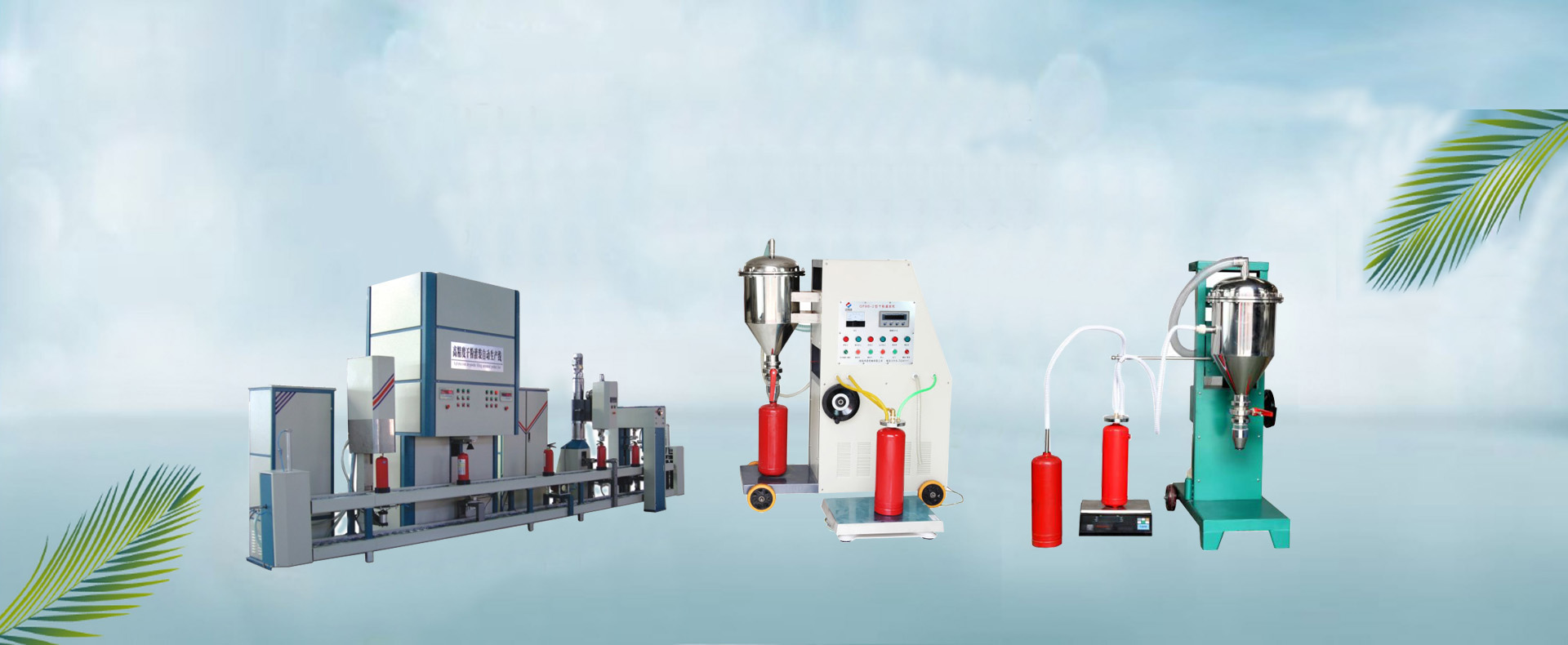

- automatic dry powder filling product line

- semi-autodry powder filling line

- Fire extinguisher dry powder filing machine

- Carbon dioxide filling machine

- Water type filling machine

- FM200 filling machine

- extinguisher Nitrogen filling machine

- N2filling and gauge checking machine

- Fire extinguisher calibration machine

- fire extinguisher drying machine

- Fire extinguisher clamper

- extinguisher airtight test machine

- cylinder pressure testing equipment

- Fire hose drying machine

- cylinder testing and blasting machine

- cylinder test pressure loader and unloader

- fire extinguish valve screwing machine

- Hose crimping machine

- 2inch hose crimping machine

- JKS-200 manual hose crimper

- DSG75 high pressure hose crimping machine

- DSG102S hose swager machine

- DSG150 hose pressing machine

- SK100 hose crimper

- JK400 hydraulic pipe locking machine

- DSG51GC steel pipe locking machine

- Hose cutting machine

- Hose skiving machine

- High pressure hose bursting test machine

- big diameter hose crimping equipment

- Nut crimping machine

- Rubber tube pressure blasting&testing mc

- Hydraulic pressure test pump

- 2D-SY hydraulic pressure test pump

- 4D-SY hydraulic test pump

- 3D-SY hydro testing equipment

- 3D-S40 automatic control test pump

- high pressure test ppump

- manual hydrostatic pump

- Computer pressure test pump

steel cylinder test pressure loader and unloader

A steel bottle type of test pressure loading and unloading machine in model of ZL-1/22.5-III is a third decade of improved test pressure device. Compared with early products, its main character is taking a pneumatic clamping device and a pneumatic facility for returning water to restored position (if the user want to use a manual way for claming, it can be order to make). Overcoming the every kind of the abuses in electronic way for returning water to restored position, our products have the higher equipment reliability and a more convenience for operation. In an old way, the returning water angle and the restored position are controlled by a journey switch. Due to the inertia moment will be changed as the loading change after the motor stop, the returning water angle and the restored position are very difficult to determine and the reliability of the journey switch is low, so it is very easy to take place an accident. However the determining the returning water angle and the restored position in a pneumatic device is determined by the stroke of the cylinder, so the returning water angle is stable and the restored position is reliable. In addition, the toppling speed of the steel bottle can be adjusted in no class by the anechoic throttle on the manual controlled valves of (returning water and restoring position), which is easy and reliable.

The steel bottle test pressure loading machine is composed of two parts: 1. a loading bottle valve device and a returning water device; 2. an electric test pressure pump and a measuring cylinder. If the user does not need the test pressure pump part, this equipment will be changed into a bottle loading and returning water machine. The user can only use the function in the bottle loading and the returning water.

The steel bottle test pressure loading machine is for the test in the resist pressure, the volume distortion and the loading & unloading the bottle valve on the steel bottle (oxygen, hydrogen, nitrogen and CO2 etc.) by a steel bottle safety monitor procedure, according to the requirements for the steel bottle inspection and the bottle valve loading & unloading in the steel bottle manufacturer, the steel bottle inspection and the filling gas station. The machine gathers machinery, electricity and pneumatics and can realize the following three functions:

a. The loading & unloading the bottle valve

b. The water pressure intensity test, the volume distortion measure & test

c. The turning over for water fall.

The equipment structure is fastness, the performance is reliable, the technology is advanced, the operation is easy, which is a necessary use device in the steel bottle manufacturer, the steel bottle inspection and the filling gas station.

The performance parameters

Voltage rating£ºAC380V/220V 50HZ

Power rating£º2.6kw

Rated test pressure£º40MPa£¨Customized£©

Specification of air bottle to be tested

Diameter£º¦µ210-¦µ220mm

Height£º1200-1600mm

Measurement£º

Main body size£º1000 ¡Á 600 ¡Á 3000mm

Electric operation area£º585 ¡Á 500 ¡Á 1000mm

Motor test pump£º655 ¡Á 480 ¡Á 1055mm

Weight£¨main body£©£º750kg

Copyright © Raoyang Hongyuan Machinery CO.,LTD. Address: Industrial Zone, Raoyang County, Hengshui City, Hebei, China