- Fire fighting machine

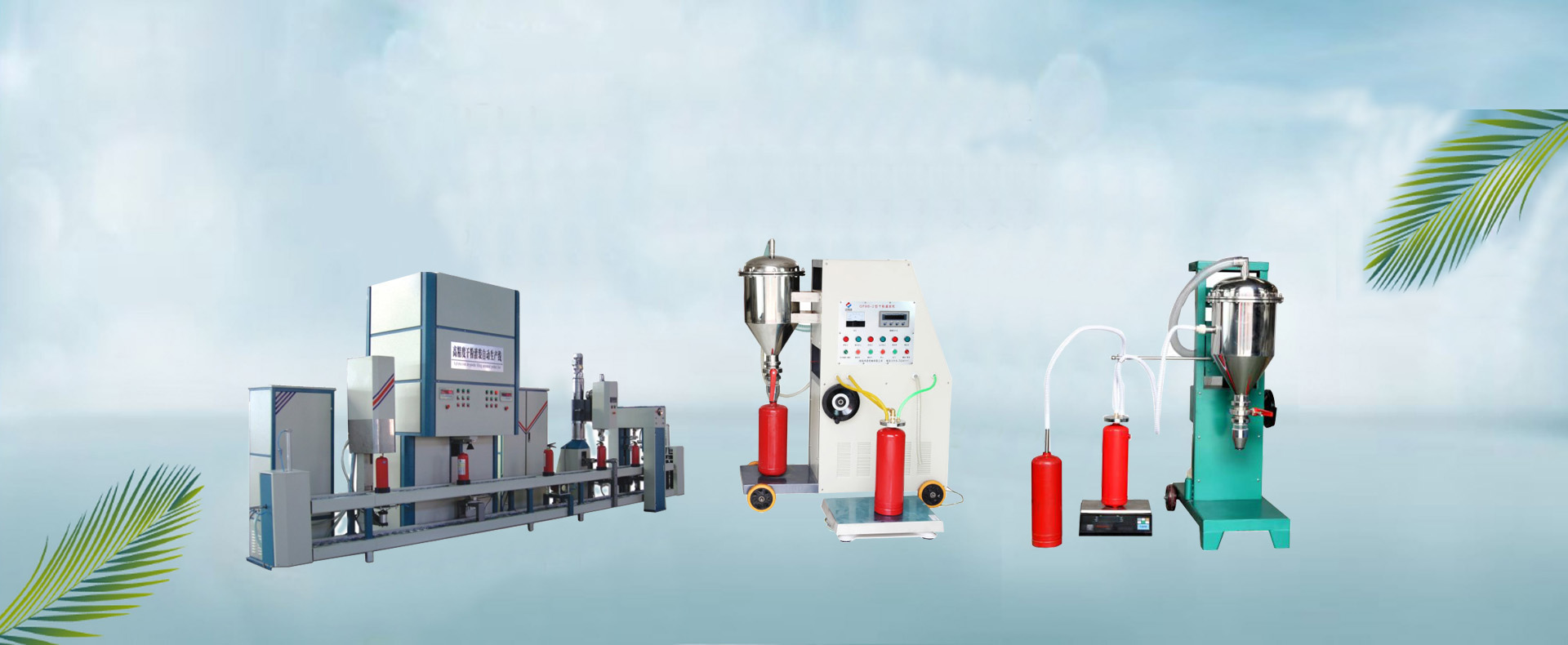

- automatic dry powder filling product line

- semi-autodry powder filling line

- Fire extinguisher dry powder filing machine

- Carbon dioxide filling machine

- Water type filling machine

- FM200 filling machine

- extinguisher Nitrogen filling machine

- N2filling and gauge checking machine

- Fire extinguisher calibration machine

- fire extinguisher drying machine

- Fire extinguisher clamper

- extinguisher airtight test machine

- cylinder pressure testing equipment

- Fire hose drying machine

- cylinder testing and blasting machine

- cylinder test pressure loader and unloader

- fire extinguish valve screwing machine

- Hose crimping machine

- 2inch hose crimping machine

- JKS-200 manual hose crimper

- DSG75 high pressure hose crimping machine

- DSG102S hose swager machine

- DSG150 hose pressing machine

- SK100 hose crimper

- JK400 hydraulic pipe locking machine

- DSG51GC steel pipe locking machine

- Hose cutting machine

- Hose skiving machine

- High pressure hose bursting test machine

- big diameter hose crimping equipment

- Nut crimping machine

- Rubber tube pressure blasting&testing mc

- Hydraulic pressure test pump

- 2D-SY hydraulic pressure test pump

- 4D-SY hydraulic test pump

- 3D-SY hydro testing equipment

- 3D-S40 automatic control test pump

- high pressure test ppump

- manual hydrostatic pump

- Computer pressure test pump

Numerical Control Ultra-Thin Intelligent Hose Crimping Machine

It performs excellently in performance. The following is a detailed introduction to its working performance:

1.Structure and design

Ultra-thin design: Adopting a forged integrated machine head, the structure is compact and stable, which significantly reduces the floor area and is convenient for flexible deployment in limited spaces.

Mold technology: Molds use special steel treated with vacuum furnace quenching, eliminating the need for galvanizing for rust prevention, which prolongs the service life of the equipment and reduces the maintenance cost in long-term use.

2.Function and efficiency

Dual-speed oil cylinder: The design takes both efficiency and precision into account. It moves quickly when idling to save time, and moves slowly when crimping to reduce the impact on oil pipes. It supports the pressure maintaining function to prevent joint rebound and ensure the firmness of crimping. This design effectively improves work efficiency and reduces the failure rate.

Multi-mode switching: Some models of hose crimping machines can be additionally equipped with more molds to increase the applicable range of rubber hose sizes, such as the commonly used 6~51mm size, which is suitable for complex pipe diameter processing. It supports multiple operation modes such as button and foot pedal control, adapting to the needs of different production scenarios.

3.Intelligence and automation

PLC/numerical control: Adopting advanced PLC or numerical control system to realize intelligent control, improving the automation degree and production efficiency of the equipment.

Quick mold change: Supports quick mold change, further shortening the production preparation time.

4.Application fields and adaptability

Widely used: The numerical control ultra-thin intelligent hose crimping machine is widely used in engineering machinery, automobile manufacturing, metallurgy, mining, oil drilling and other fields.

5.Other performance characteristics

Stability and reliability: After strict testing and certification, the equipment shows high stability and reliability in long-term use.

After-sales service: The manufacturer provides perfect after-sales service and technical support to ensure that the equipment can be maintained in a timely and effective manner during use.

To sum up, the numerical control ultra-thin intelligent hose crimping machine performs excellently in structure and design, function and efficiency, intelligence and automation, application fields and adaptability, as well as stability and reliability. These performance characteristics make the equipment an ideal choice for efficient and precise processing of hydraulic pipe fittings.

Copyright © Raoyang Hongyuan Machinery CO.,LTD. Address: Industrial Zone, Raoyang County, Hengshui City, Hebei, China