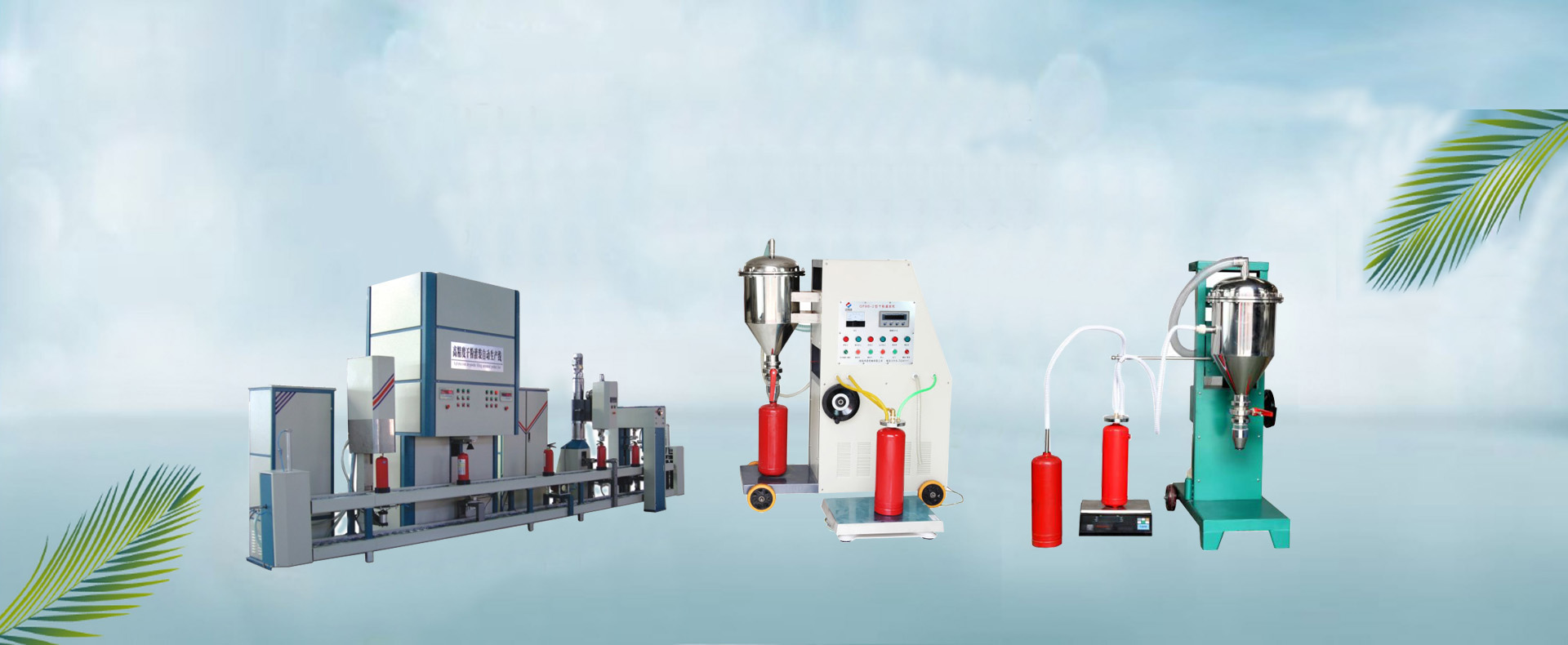

- Fire fighting machine

- automatic dry powder filling product line

- semi-autodry powder filling line

- Fire extinguisher dry powder filing machine

- Carbon dioxide filling machine

- Water type filling machine

- FM200 filling machine

- extinguisher Nitrogen filling machine

- N2filling and gauge checking machine

- Fire extinguisher calibration machine

- fire extinguisher drying machine

- Fire extinguisher clamper

- extinguisher airtight test machine

- cylinder pressure testing equipment

- Fire hose drying machine

- cylinder testing and blasting machine

- cylinder test pressure loader and unloader

- fire extinguish valve screwing machine

- Hose crimping machine

- 2inch hose crimping machine

- JKS-200 manual hose crimper

- DSG75 high pressure hose crimping machine

- DSG102S hose swager machine

- DSG150 hose pressing machine

- SK100 hose crimper

- JK400 hydraulic pipe locking machine

- DSG51GC steel pipe locking machine

- Hose cutting machine

- Hose skiving machine

- High pressure hose bursting test machine

- big diameter hose crimping equipment

- Nut crimping machine

- Rubber tube pressure blasting&testing mc

- Hydraulic pressure test pump

- 2D-SY hydraulic pressure test pump

- 4D-SY hydraulic test pump

- 3D-SY hydro testing equipment

- 3D-S40 automatic control test pump

- high pressure test ppump

- manual hydrostatic pump

- Computer pressure test pump

Replacement Process of Hose Crimping Machine Accessories

The replacement process of hose crimping machine accessories usually includes the following steps:

1.Preparation stage

Confirm accessory model:

Before replacing accessories, it is first necessary to confirm the model and specification of the accessories to be replaced to ensure that the purchased accessories are compatible with the equipment.

Prepare tools and materials:

According to the specific needs of replacing accessories, prepare corresponding tools (such as screwdrivers, wrenches, hexagon socket tools, etc.) and materials (such as new accessories, lubricants, etc.).

Disconnect the power supply:

Before carrying out any maintenance or replacement of accessories, be sure to disconnect the power supply of the equipment to ensure safety during operation.

2.Remove old accessories

Locate and remove screws:

Use appropriate tools to locate and remove the screws that fix the old accessories. During the disassembly process, be careful not to damage the surrounding parts or structures.

Carefully take out the old accessories:

After removing the screws, carefully take out the old accessories from the equipment. During the taking-out process, be careful not to damage other parts or lines connected to them.

3.Install new accessories

Clean the installation position:

Before installing new accessories, clean the installation position to ensure that there is no dust, debris or residue. This helps to ensure that the new accessories can be firmly installed on the equipment.

Align and install new accessories:

Align the new accessories with the installation position, and fix them with appropriate tools. During the fixing process, be careful not to be too tight or too loose to ensure that the accessories can work normally and will not be damaged.

Connect lines and pipes:

If the new accessories need to be connected to lines or pipes, please ensure that they are connected correctly according to the equipment manual or drawings. During the connection process, be careful not to connect the lines or pipes incorrectly to ensure that the equipment can operate normally.

4.Testing and debugging

Power-on test:

After installing the new accessories, reconnect the power supply of the equipment and conduct a power-on test. During the test, pay attention to observing whether the equipment operates normally and whether the new accessories work normally.

Function test:

According to the equipment manual or operation manual, conduct a function test on the new accessories to ensure that they can work normally. During the test, pay attention to recording any abnormalities or problems for timely resolution.

Adjustment and optimization:

If any problems or abnormalities are found during the test, adjustments and optimizations are needed to ensure that the equipment can operate normally. This may include adjusting the position of accessories, tightening screws, or replacing other related parts, etc.

5.Completion and recording

Sort out tools and materials:

After completing the replacement process, sort out the used tools and materials and put them back in place for next use.

Record replacement information:

Record the information of the replaced accessories in the equipment maintenance record or log, including accessory model, replacement date, maintenance personnel, etc., for subsequent tracking and reference.

Please note that the above process may vary depending on the equipment model and accessory type. Therefore, before replacing accessories, be sure to refer to the equipment manual or contact the professional maintenance personnel of Hongyuan Machinery for consultation and guidance.

Copyright © Raoyang Hongyuan Machinery CO.,LTD. Address: Industrial Zone, Raoyang County, Hengshui City, Hebei, China