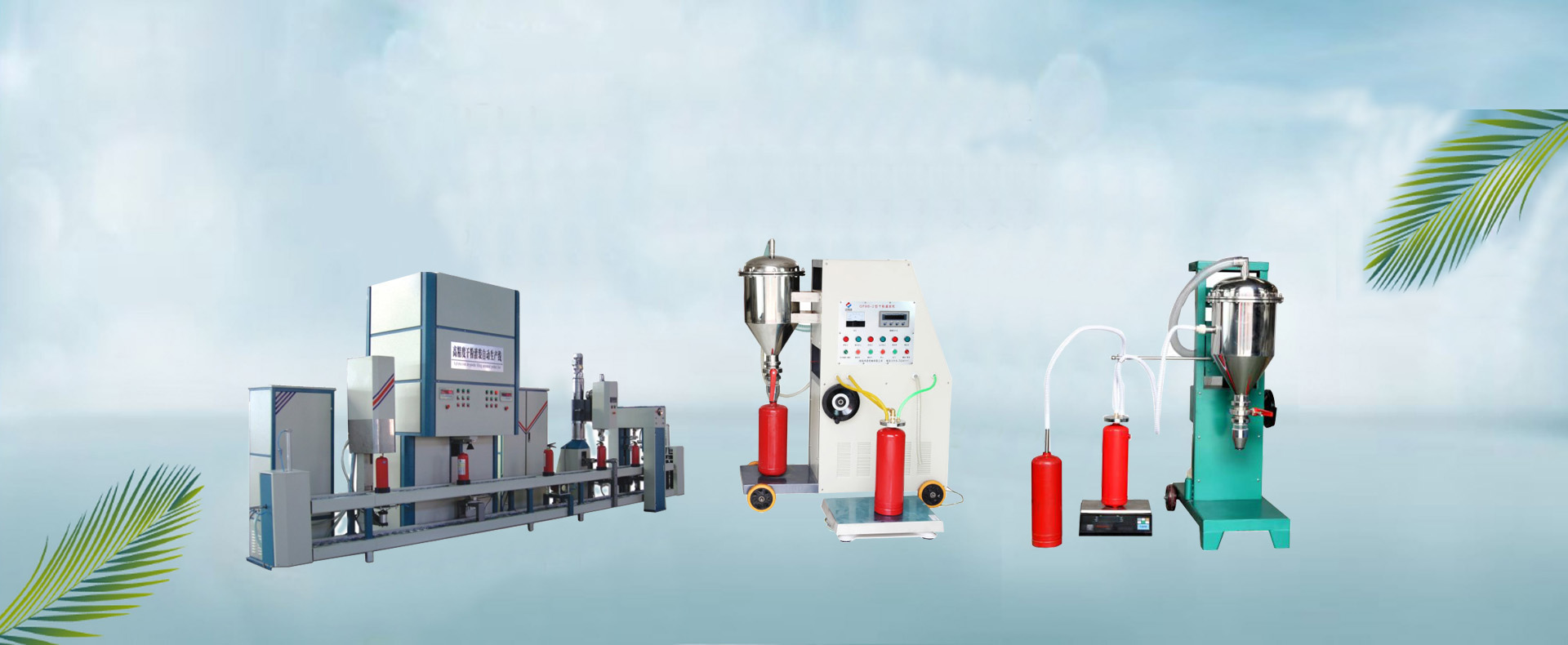

- Fire fighting machine

- automatic dry powder filling product line

- semi-autodry powder filling line

- Fire extinguisher dry powder filing machine

- Carbon dioxide filling machine

- Water type filling machine

- FM200 filling machine

- extinguisher Nitrogen filling machine

- N2filling and gauge checking machine

- Fire extinguisher calibration machine

- fire extinguisher drying machine

- Fire extinguisher clamper

- extinguisher airtight test machine

- cylinder pressure testing equipment

- Fire hose drying machine

- cylinder testing and blasting machine

- cylinder test pressure loader and unloader

- fire extinguish valve screwing machine

- Hose crimping machine

- 2inch hose crimping machine

- JKS-200 manual hose crimper

- DSG75 high pressure hose crimping machine

- DSG102S hose swager machine

- DSG150 hose pressing machine

- SK100 hose crimper

- JK400 hydraulic pipe locking machine

- DSG51GC steel pipe locking machine

- Hose cutting machine

- Hose skiving machine

- High pressure hose bursting test machine

- big diameter hose crimping equipment

- Nut crimping machine

- Rubber tube pressure blasting&testing mc

- Hydraulic pressure test pump

- 2D-SY hydraulic pressure test pump

- 4D-SY hydraulic test pump

- 3D-SY hydro testing equipment

- 3D-S40 automatic control test pump

- high pressure test ppump

- manual hydrostatic pump

- Computer pressure test pump

Fire Extinguisher Annual Inspection and Maintenance Process and Precautions

Fire extinguisher annual inspection and maintenance is a key measure to ensure its reliability at critical moments. The following are specific processes and precautions, sorted out in combination with national standards and professional operation requirements:

1.Standard process for annual inspection and maintenance

Information registration and preliminary inspection

Fill in the original information record form, recording information such as fire extinguisher model and production date.

Visually inspect the appearance of the bottle body (rust, deformation), the clarity of the nameplate, whether the pressure gauge pointer is in the green area, and confirm whether it meets the scrap standard (for example, the bottle body is burned, deformed £¾1/3 of the surface area needs to be scrapped).

Safe disassembly and pressure relief

Slowly relieve pressure through the flat-head valve, ensure that there is no pressure in the bottle before disassembling the valve, and avoid dangers caused by residual pressure.

Extinguishing agent recovery and bottle body treatment

Special equipment recovers dry powder or liquid extinguishing agent to prevent environmental pollution; different extinguishing agents need to be handled separately, and mixed loading is prohibited.

The bottle body is cleaned and dried to ensure internal dryness (necessary for non-water-based fire extinguishers).

Key component inspection and replacement

Hydrostatic test of pressure-bearing components: The cylinder and gas storage bottle are subjected to hydrostatic test one by one to test the pressure-bearing capacity (carbon dioxide bottles need additional detection of residual deformation rate).

Part replacement:

Deformed/aged sealing rings, nozzles, and spray hoses must be replaced;

Pressure indicators with excessive error or damage need to be replaced;

All parts must use original or certified accessories.

Re-filling and air tightness test

Fill extinguishing agent and driving gas (such as nitrogen) according to standards, and reweigh each one to confirm the filling amount.

After filling, place it flat for air tightness test to detect leakage (pressure holding time ¡Ý30 seconds).

Final assembly and marking

Assemble qualified components, weigh and check the total mass.

Paste the new version of the maintenance certificate (including maintenance date and agency information), and update the maintenance record form.

2.Key precautions

Safety operation specifications

It is necessary to confirm that there is no pressure in the bottle before disassembly, and maintenance personnel need to wear protective equipment (dust mask, gloves).

During the hydrostatic test, the residual extinguishing agent must be poured into a special waste liquid tank to avoid mixed pollution.

Scrap judgment standards

Service life requirements: dry powder fire extinguishers must be scrapped after 10 years, carbon dioxide after 12 years; dry powder must be maintained for the first time after 5 years from the factory (maintenance is required every 2 years after the first maintenance).

Bottle body defects: rust area £¾10%, severe deformation, head cracks, structural damage (such as pressure handle deformation).

Cycle and repair requirements

Dry powder fire extinguishers require their first maintenance 3 years after manufacture, and subsequent maintenance is carried out every 2 years; the cycle needs to be shortened in harsh environments (high temperature, humidity).

The single repair quantity shall not exceed 1/4 of the total number of fire extinguishers in the area to avoid affecting fire fighting standby.

Daily self-inspection points

Monthly inspection: whether the pressure gauge pointer is in the green area, whether the safety pin is intact, and whether the nozzle is blocked.

Annual inspection: entrust a professional agency to test the tightness (carbon dioxide leakage rate £¾3% is scrapped) and driving gas pressure.

3.Special requirements for different types of fire extinguishers

Type Maintenance cycle Scrap life Special inspection items

Dry powder fire extinguisher First inspection 3 years after leaving the factory, every 2 years thereafter 10 years Residual dry powder moisture content detection

Water-based fire extinguisher First inspection 3 years after leaving the factory, every 1 year thereafter 6 years Antifreeze effectiveness test

Carbon dioxide fire extinguisher First inspection 5 years after leaving the factory, every 2 years thereafter 12 years Bottle residual deformation rate, leakage rate

Regular maintenance is not only a legal requirement (Fire Law and GB 50444 and other standards), but also a core measure to avoid safety hazards. If abnormal pressure, bottle damage or overdue inspection is found, it should be stopped immediately and sent for repair. Unauthorized disassembly or refilling is strictly prohibited!

Copyright © Raoyang Hongyuan Machinery CO.,LTD. Address: Industrial Zone, Raoyang County, Hengshui City, Hebei, China