- Fire fighting machine

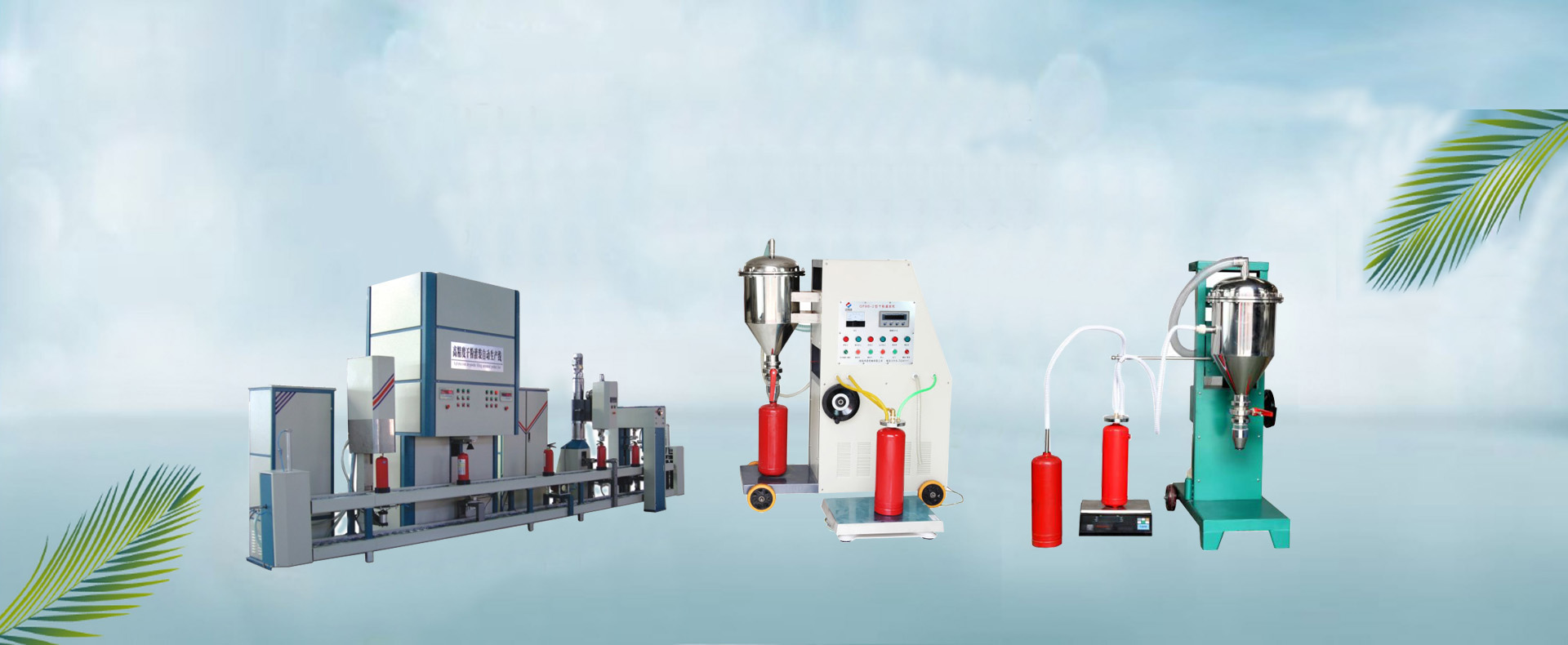

- automatic dry powder filling product line

- semi-autodry powder filling line

- Fire extinguisher dry powder filing machine

- Carbon dioxide filling machine

- Water type filling machine

- FM200 filling machine

- extinguisher Nitrogen filling machine

- N2filling and gauge checking machine

- Fire extinguisher calibration machine

- fire extinguisher drying machine

- Fire extinguisher clamper

- extinguisher airtight test machine

- cylinder pressure testing equipment

- Fire hose drying machine

- cylinder testing and blasting machine

- cylinder test pressure loader and unloader

- fire extinguish valve screwing machine

- Hose crimping machine

- 2inch hose crimping machine

- JKS-200 manual hose crimper

- DSG75 high pressure hose crimping machine

- DSG102S hose swager machine

- DSG150 hose pressing machine

- SK100 hose crimper

- JK400 hydraulic pipe locking machine

- DSG51GC steel pipe locking machine

- Hose cutting machine

- Hose skiving machine

- High pressure hose bursting test machine

- big diameter hose crimping equipment

- Nut crimping machine

- Rubber tube pressure blasting&testing mc

- Hydraulic pressure test pump

- 2D-SY hydraulic pressure test pump

- 4D-SY hydraulic test pump

- 3D-SY hydro testing equipment

- 3D-S40 automatic control test pump

- high pressure test ppump

- manual hydrostatic pump

- Computer pressure test pump

How to Judge Whether a Fire Extinguisher Needs Annual Inspection?

To judge whether a fire extinguisher needs annual inspection or maintenance, a comprehensive inspection should be carried out in combination with the following key indicators to ensure that it is in an effective standby state:

1.Basic inspection items (user self-inspection)

Pressure gauge status:

Pointer in green area: normal pressure, can be used normally.

Pointer in red area: insufficient pressure, need to be repaired or replaced immediately.

Pointer in yellow area: excessive pressure, need to be inspected by professionals.

Appearance integrity:

Bottle body: rust area £¾1/3 of the surface area, deformation, cracks or fire marks need to be scrapped.

Nozzle/hose: aged, damaged, blocked need to be replaced.

Safety pin and lead seal: missing or damaged need to be sent for inspection.

Marking and date:

Production date: confirm the production time through the steel stamp on the bottle body.

Maintenance label:

Blurred, missing labels or incomplete information (no maintenance date/agency) need to be sent for inspection.

Expired maintenance certificate (for example, dry powder fire extinguishers need to be inspected every 2 years after the first maintenance).

2.Hard standards for mandatory inspection/scrapping

Exceeding service life

Type First maintenance time Scrap life

Dry powder fire extinguisher 5 years after leaving the factory 10 years

Water-based fire extinguisher 3 years after leaving the factory 6 years

Carbon dioxide fire extinguisher 5 years after leaving the factory 12 years

Special scenarios require shortened cycles

Harsh environment: high temperature, high humidity, corrosive places, dry powder fire extinguishers are recommended to be inspected annually.

High-frequency use: such as shopping malls, gas stations, need comprehensive inspection every 1 year.

Abnormal conditions:

Carbon dioxide fire extinguisher leakage rate £¾3%;

Dry powder extinguishing agent caking or excessive water content.

3.Professional testing requirements (need to be operated by institutions)

Tightness detection:

Carbon dioxide fire extinguishers need annual inspection of leakage rate (more than 3% is scrapped).

Functional test:

Hydrostatic test (dry powder/carbon dioxide fire extinguishers once every 5 years).

Annual inspection of antifreeze effectiveness of water-based fire extinguishers.

Summary: When must it be sent for inspection?

Send for inspection immediately: abnormal pressure (red/yellow area), missing labels, appearance defects.

Send for inspection on schedule: reach the first maintenance period (such as dry powder 5 years after leaving the factory) or subsequent cycles (such as dry powder every 2 years).

Mandatory scrapping: exceeding service life, excessive rust, bottle body deformation/cracks.

Reminder: Units that fail to inspect fire extinguishers regularly will face penalties under the Fire Law. Daily self-inspection is recommended once a month, focusing on the pressure gauge and appearance.

Copyright © Raoyang Hongyuan Machinery CO.,LTD. Address: Industrial Zone, Raoyang County, Hengshui City, Hebei, China